Understanding China CNC Turning Parts: Revolutionizing Metal Fabrication

The world of manufacturing is continuously evolving, and at the forefront of this evolution are China CNC turning parts. These components play a vital role in various industries, enhancing productivity, precision, and efficiency. This article delves into what CNC turning parts are, their significance in metal fabrication, and how they can give your business a competitive edge.

What are CNC Turning Parts?

CNC, or Computer Numerical Control, turning is a manufacturing process wherein a machine tool rotates a workpiece while a stationary cutting tool removes material. This process creates intricate shapes and forms with precision, making it a favored choice in metal fabrication.

Key Characteristics of CNC Turning Parts

- High Accuracy: CNC turning parts can achieve tolerances as tight as ±0.005 mm.

- Repeatability: Once programmed, CNC machines can produce identical parts consistently.

- Customization: Parts can be tailored to meet specific requirements, designs, and applications.

- Complex Geometries: Capable of producing intricate designs that are difficult to achieve through traditional machining.

- Efficiency: CNC machines can operate continuously, thus maximizing production output.

The Importance of China CNC Turning Parts in Metal Fabrication

The role of China CNC turning parts in the manufacturing sector cannot be overstated. They are essential for numerous applications, including aerospace, automotive, medical devices, and electronics. Here are some reasons why they are so important:

1. Cost-Effectiveness

Manufacturers are always looking for ways to reduce costs while maintaining quality. By utilizing CNC turning parts sourced from China, businesses can significantly lower their production expenses. The reasons include:

- Lower Labor Costs: Manufacturing in China often involves lower labor costs, allowing for more affordable pricing of parts.

- Economies of Scale: Large-scale production facilities can offer competitive rates due to high-volume outputs.

2. Advanced Technology

China boasts some of the most advanced CNC machining technologies available. These technologies allow for the following:

- Precision Engineering: High-quality machining techniques ensure that the finished product meets exact specifications.

- Integration of Latest Innovations: China's manufacturers often have access to cutting-edge technology, which leads to better materials and processes.

3. Variety of Materials

Another benefit of sourcing from China is the variety of materials available for CNC turning parts. Chinese manufacturers can work with various metals, including:

- Aluminum

- Stainless Steel

- Brass

- Copper

- Carbon Steel

Applications of CNC Turning Parts

China CNC turning parts are integral to various industries and applications. Some notable examples include:

Aerospace Industry

In aviation and aerospace, precision is paramount. CNC turning parts are used to manufacture components like:

- Landing gear assemblies

- Engine mounts

- Structural components

Automotive Sector

The automotive industry relies heavily on CNC turning for producing high-quality parts such as:

- Engine components

- Transmission parts

- Suspension systems

Medical Applications

Health care technology requires components that adhere to strict regulations and standards. CNC turning parts for medical devices include:

- Surgical instruments

- Prosthetic devices

- Diagnostic equipment

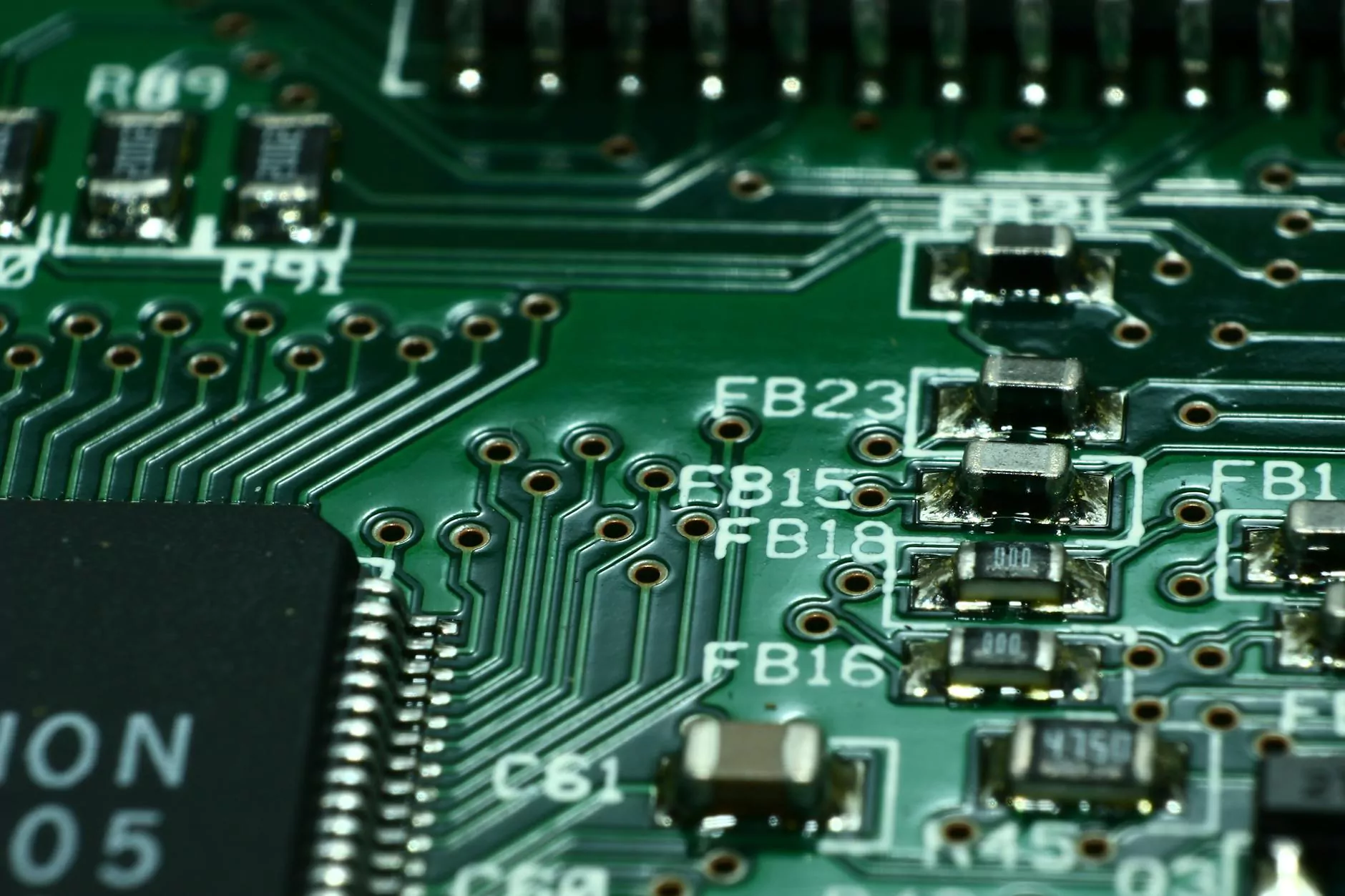

Electronics Manufacturing

The electronics industry benefits from the customization capabilities CNC turning offers, resulting in parts for:

- Connectors

- Housing for electronic devices

- Heat sinks

Advantages of Using CNC Turning Parts from China

Companies considering the shift to using China CNC turning parts can expect numerous advantages:

1. Faster Production Times

As CNC machines can operate continuously and be programmed for specific tasks, they drastically reduce production time compared to manual machining. Additionally, the design process is enhanced by using advanced software that streamlines operations.

2. Enhanced Quality Control

Manufacturers in China often implement robust quality control systems that monitor production at every stage, ensuring that products meet international standards.

3. Flexibility in Production

CNC technology allows for adjustments to be made quickly without needing reconfiguration of the machinery, facilitating rapid response to market demands.

4. Global Supply Chain Integration

China’s established supply chains allow for smooth logistics and delivery systems, minimizing lead times in parts procurement.

Challenges and Considerations

While there are many benefits to sourcing China CNC turning parts, companies should also be aware of potential challenges:

1. Language Barriers

Working with manufacturers in China may present communication challenges. However, many companies employ staff who are fluent in English and understand international business protocols.

2. Quality Assurance

Ensuring the quality of parts requires diligence. Businesses should perform due diligence in choosing a manufacturer with a proven track record in quality assurance practices.

3. Intellectual Property Concerns

Intellectual property protection can be more complex in global sourcing. Companies should execute contracts and NDAs to protect their designs and technologies.

Conclusion

In conclusion, China CNC turning parts are essential for many modern manufacturing processes, offering cost-effective, high-quality solutions across various industries. Their application in aerospace, automotive, medical, and electronic sectors illustrates their versatility and importance in today’s global market. By understanding the benefits, applications, and potential challenges, businesses can make informed decisions when considering CNC parts from China.

About Deepmould

Deepmould.net is a leading manufacturer specializing in metal fabrication and CNC solutions. With our expertise in China CNC turning parts, we provide high-quality products tailored to meet the specific needs of our clients. Our commitment to innovation, quality, and customer satisfaction sets us apart as a trusted partner in the manufacturing industry. For more information, visit our website or contact us today.